1946 Royal Enfield G350 in the basement.

Several years back a friend of ours let us know about a stash of English bikes in a basement in Connecticut. The owner wanted to find a new home for them, it was a “must take all” deal, and the deal came with a sincere desire to have it go to enthusiasts and not to profit-only seekers.

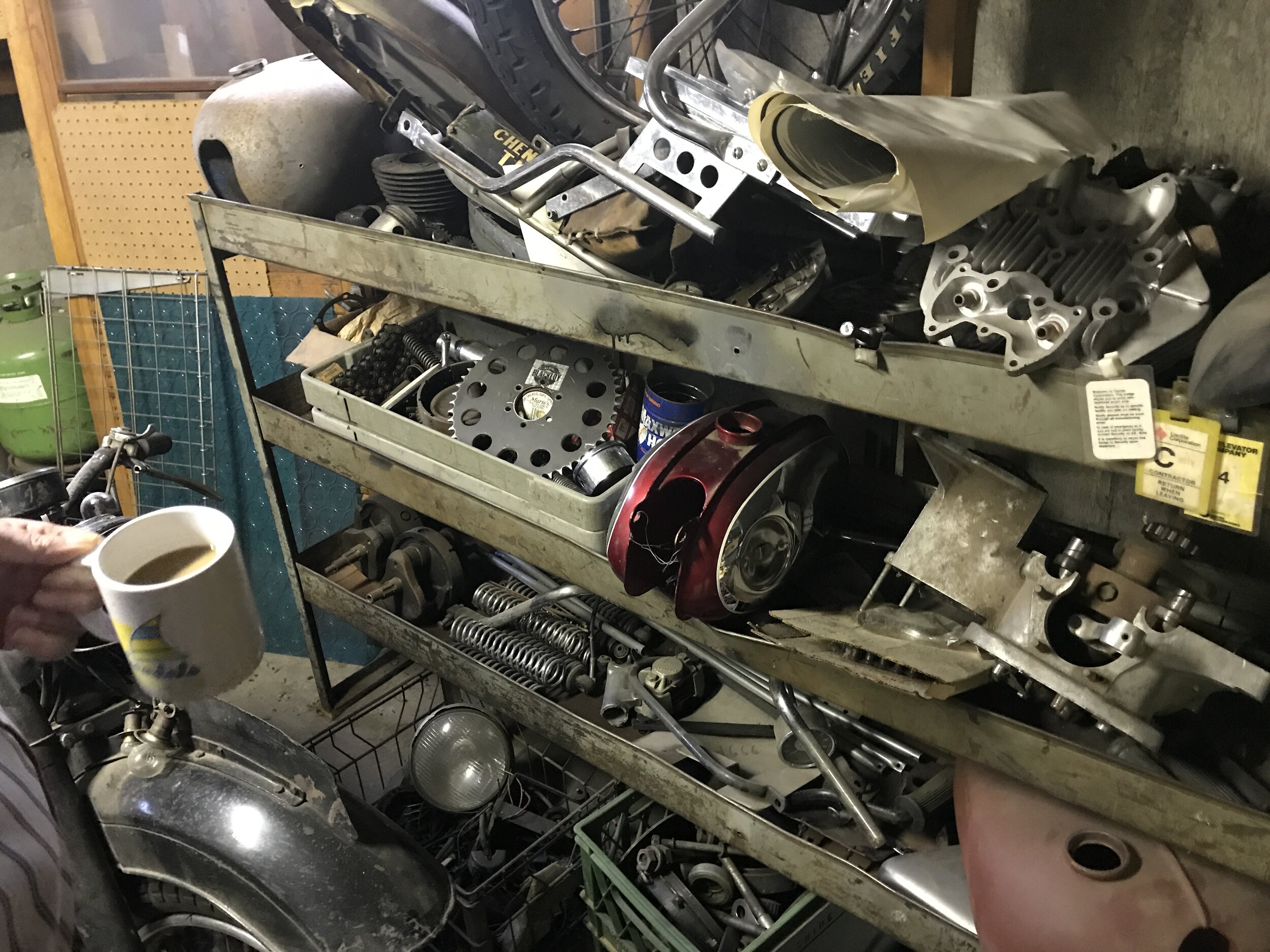

We went down to have a look and found a BSA Bantam 175, a Triumph Daytona 500, a rigid framed Royal Enfield 350, a Triumph tiger 750, and a very cool Royal Enfield bicycle; as well as boxes of spare parts and coffee cans full of little bits and hardware. We knew we weren’t leaving empty handed as soon as we saw it. There was one last catch: “must take all” had a double meaning, as in “must take all up these narrow steep basement bulkhead steps.” We don’t back down from a challenge though, so a deal was made, money changed hands, and up the steep steps it all went. After handing over the Enfield pedal bike to our friend as a finder’s fee, we loaded it all up and brought it back to shop.

Back at the shop we split things up between us, with the two Triumph’s going to Bailey and her family and the Enfield, Bantam, and remaining parts staying at the shop. In the end the Tiger was sold off as a project as it was fairly rough, and the Bantam was likewise sold to an enthusiast who has since brought it back to a very good state. The Triumph Daytona remains under the watchful care of Bailey and her father, and the Royal Enfield 350 has until very recently sat as a display piece in our shop.

It’a tough in a shop to find time to work on things that don’t have an hourly rate attached to them, particularly a young shop like ours, so until recently we had only managed to throw some oil into the cylinder, check that the motor was free, and verify that there was indeed no spark. Oh, and we’d also determined that it was a 1946 G350 model. The rest of our work on it consisted of putting it places where it looked good, and having conversations about how cool it’ll be to “get that going someday.”

Well, this winter that day finally came. We pulled the Enfield off it’s most recent perch (the display table it’s been sharing with our merchandise) and put it up on a workbench.

Step one was to determine why there was no spark from the BTH magneto. We sat down to clean the points, and discovered that there were- no points. More accurately there was one point- the outer point arm had broken leaving a lonely contact rotating around all by itself.

Digging through the pile of spares that we’d gotten with it turned up a brand new set of points, which dropped in without fuss. A quick prod on the kicker and we had spark! Talk about easy…

Quickly, we gave it a basic pre-check that included setting the valves, adding oil, and cleaning up the carb. Instead of trying to fill the still-dirty tank, or rig up our external fuel bottle to the compression fittings on the metal line on the bike, we simply filled the float bowl directly and left it open.

A few kicks on the starter and nothing. We changed roles doing the kicking, tried several different variations on procedure, and finally got something to go boom- but sadly it was right through the carb intake. As in backwards. We were able to repeat this result multiple times, which meant something really wasn’t right.

Time to get serious.

We set the piston at 3/8” before top dead center on the compression stroke (as per the ancient manual we received with the bike), and checked what the points were doing. They were not doing what they should be. Instead of having just opened at that point, they were wide open and had been for too long to be only “a little out”. In fact we determined that they were set to fire in the vicinity of top dead center on overlap- hence our backfires through the carb.

We then set the motor back to it’s proper firing point, and pulled off the timing chest cover. We were able to partially slide the intermediate timing gear out of the gear train and thus rotate the magneto independently. We spun the mag until the points were just opening, then slid the intermediate gear back into position. We then buttoned up the timing chest cover, topped up the fuel in our completely safe open float bowl, and gave it another kick. After a few tries with some encouraging pops (this time out of the correct side of the engine), we were rewarded with a satisfying blast out of the muffler-less header as it roared to life (and spit out A LOT of acorns).

Immediately, we realized we didn’t know how to turn it off…Thankfully, we are all brave here in the shop, and Bailey selflessly and without hesitation pulled the spark plug wire off the plug, getting a nice shock in the process. After a long distance high-five (it’s still Covid after all), we made sure the camera was running this time and did the whole thing again, Bailey again throwing herself in the path of those unfriendly electrons to stop the machine from running.

Click here to see the Instagram video.

Now that we know it runs, our plan is to go through the whole bike in a first pass, rather than try to perfect each system/area before moving on to the next. The reason for this is that the places to find parts readily for these are few and far between, and it’s best to consolidate parts orders as much as possible. We are generating a list of bits big and small, and will hopefully be able to get what we need in an order or two. Meanwhile, as we wait for those parts, we can work on things like wiring and making replacement cables. We’re very much looking forward to pottering around on this ancient beauty this coming season, and having it join our Swingin’ (kickstart) Hot (air-cooled) Singles (single cylinder) club. Maybe Pete will even tackle The Unsprung on it…